Have you ever sat at a restaurant, eagerly awaiting a dish you ordered, and wondered exactly how many grams of salt would be added, or how finely the onion would be sliced? Probably not. Instead, you place your trust in the chef’s expertise, confident that their experience and precision will result in a dish that’s perfectly seasoned and prepared. This trust in expertise and meticulous attention to detail parallels another, perhaps more technical realm: the world of measurement tool calibration, specifically the calibration of dynamometers.

Just as a chef uses their knowledge to enhance a dish, engineers and technicians rely on calibrated instruments to ensure the accuracy and reliability of their measurements. But, before diving into the specifics, let’s explore a fundamental question: Do you know if your team ever uses dynamometers and for what purposes?

The Role of Dynamometers in Precision Measurement

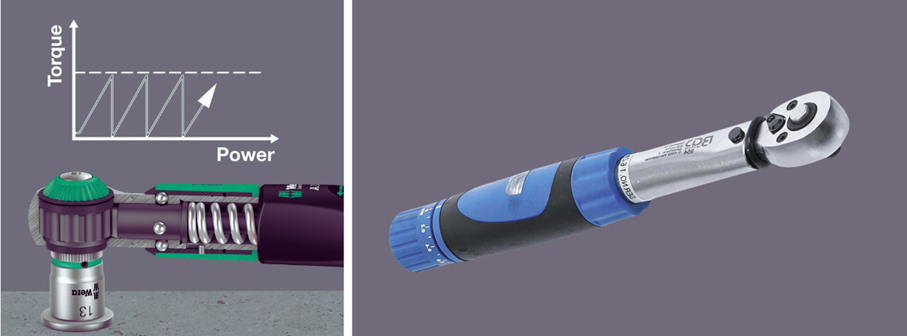

Dynamometers are crucial tools used across various industries to measure force, torque, or power. From testing the power output of an aircraft engine in the aviation industry to ensuring a car engine performs efficiently in the automotive sector, dynamometers help maintain the high standards of safety, efficiency, and reliability.

The Importance of Calibration

Just like trusting a chef’s judgment in seasoning a dish, trusting the accuracy of a dynamometer is essential. Calibration ensures that these measurement tools provide accurate and reliable data. Without calibration, the data from these instruments could lead to incorrect conclusions, much like an improperly seasoned dish could lead to dissatisfaction.

Tailoring Calibration to Industry Needs

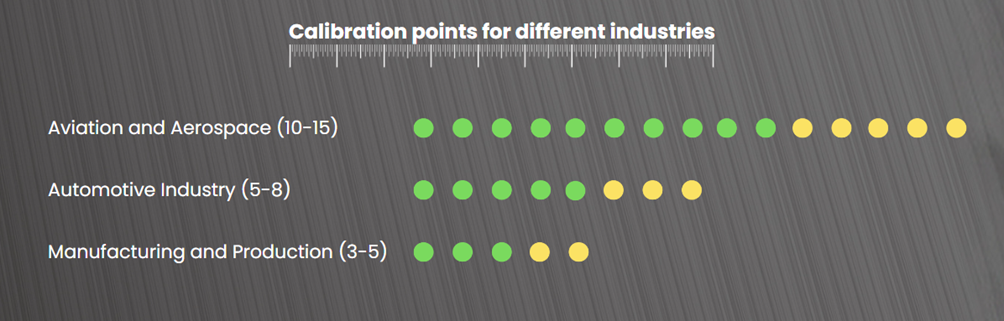

Calibration is not a one-size-fits-all process. Different industries require different calibration standards, much like the varied techniques a chef uses to prepare ingredients for different dishes.

The Frequency of Calibration: A Scheduled Necessity

Just as a chef regularly sharpens their knives to maintain their cutting precision, dynamometers require periodic calibration to ensure their measurement accuracy. The frequency of this calibration can vary, influenced by factors such as the instrument’s use, the environmental conditions it’s exposed to, and the critical nature of the measurements it provides.

Conclusion: The Essence of Trust in Precision

In the end, just as you trust a chef to deliver a dish that meets your expectations without knowing the exact measurements of each ingredient, you must also trust in the precision and reliability of your measurement tools. The calibration of dynamometers is a critical aspect of this trust, ensuring that every measurement they provide is accurate and dependable.

Whether you’re ensuring the safety of an aircraft, the efficiency of a vehicle, or the productivity of industrial machinery, understanding the when, why, and how of dynamometer calibration is akin to understanding the secret recipes behind your favorite dishes. It’s all about trusting the experts and the processes they rely on to deliver perfection.